Hair Depositing Mechanism

During one of my classes at WPI, iRobot had students develop a hair depositing mechanism that would embed hair into carpet. This project took place over the course of 6 weeks where several prototypes were created. My classmates Owen Buckingham and Daniel Ali participated in this project with me.

The goals for this project was to create a device that could evenly place hair throughout a 4 foot by 4 foot pen so that iRobot could test out their robot vacuums. The product needed to be compact, light weight, and safe for an operator to use.

The mechanism went through several phases of development during testing. The initial idea was to use static electricity to transfer the hair out of a storage system and carry it onto the ground.

The theory behind the static system was to use a high voltage input to create an electric charge potential difference between the roller and the hair. The charge would then be stored in a dielectric material such as Mylar.

High voltage boost step up inverter used to create high voltage line and a dipole latus structure to generate static

Unfortunately, this system didn't seem to attract the amount of hair we were hoping for. Even though it could pickup small strands, it wasn't strong enough to pull apart the clumps of hair that we were feeding the system. However, we did notice that the Mylar sheet was able to build up enough charge if we rubbed some fabric on it. This accident led to our second prototype.

First version of our static roller assembly

Rubber bands kept the Mylar sheet in place while the glue dried.

This model used an adhesive felt sheet that was intended to rub against the roller. Unfortunately, the felt was too thin for the roller to properly compress into the material to build static charge. The further we tried to inset the roller into the material, the more it would collide with the 3d printed frame. Additionally, the roller was not able to spin easily since the mating surface with the carpet was smooth, not generating enough friction for the roller to spin.

To fix these issues, we slotted the frame that the roller sat in and sprung load the roller into a thicker piece of wool to generate static. We also added some rough edges to sink into the ground, allowing the roller to spin.

During testing, we also found that packing tape had better static properties than the Mylar sheet, so we switched to that for the next version.

Version 2 with the sprung loaded roller.

Even after making adjustments to let the roller spin, we weren't able to build enough static to pull the hair though our system. Although we felt like there was merit to this design concept, we decided to try and pursue a different prototype so that we could create a functioning model to hand off to iRobot.

Since we were having the most difficulty with feeding hair out of our system, we came up with the idea of having a compliant feeder roller that would pinch the hair out of our storage system.

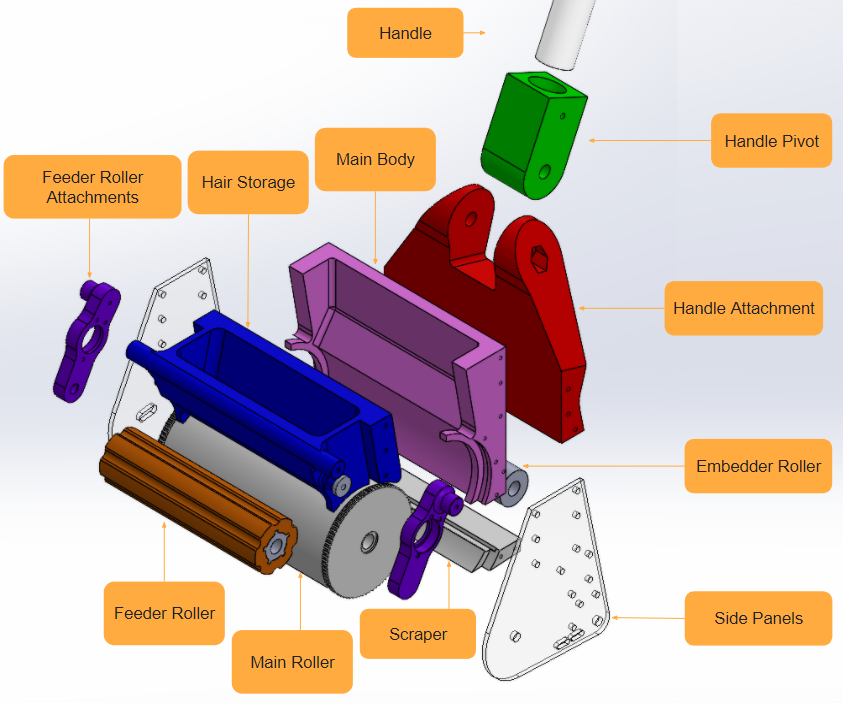

Labeled exploded view of final prototype

The feeder roller system uses a spring loaded foam roller that pinches the hair out of the storage compartment. The compliance between the sprung pivot and the custom cast foam roller allowed for varying thicknesses of hair bundles to pass through the mechanism.

Process of molding the custom foam feeder roller.

Hair rolling test.

As you can see in the video, the entire clump of hair was removed from the storage system.

We recommended to iRobot that they should look into hair agitation methods to prevent clumping from happening. This likely would include a separate mechanism that was combined with this system to provide the pinch rollers with smaller bundles of hair.

Alternatively, having pre-spooled lengths of synthetic hair could make depositing hair easier. This way, a device could cut the pieces of hair to the desired length before depositing onto the ground, avoiding the clumping issue altogether.